Smarter Human x Smarter Tech: Improve Semiconductor Manufacturing Standard with TOYO Automation, Quality that Never Failed You

In today’s manufacturing landscape, automation has become an indispensable part of the manufacturing process, particularly in industries where extreme precision and speed are required, such as electronics parts, semiconductors, medical devices, and electric vehicles. These industries require a high initial investment, but the benefits of automation cannot be ignored.

The industrial automation market offers a wide range of products at different price points and from different brands. Although German or Japanese brands are well-known in Thailand for their premium quality, many people overlook or are unfamiliar with the smart machines and technology offered by Taiwanese brands, which provide comparable quality to Japanese products but with a slightly lower price point. Taiwan’s advanced technology is one of the reasons why it has become the capital for global semiconductor production.

‘Automation’ a Must for Factory That Can’t Be Avoided but Business Can ‘Choose’

As the manufacturing industry becomes increasingly competitive and market changes occur more rapidly, technology is becoming an essential tool for success. Automation technology is particularly critical in addressing labor shortage and creating the necessary flexibility to adapt to rapidly changing market demands. Investing in automation technology is a high-value proposition, but finding skilled labor to implement these technologies can be a significant challenge, particularly for small and medium-sized businesses.

TOYO Automation, a professional provider of factory automation solutions and a frequent Taiwan Excellence Award winner, understands that there are many barriers to factory transformation, such as labor and skill shortage, as well as the high cost of automation technology. Siddhesh Uttam Pilankar, a Sales Engineer at TOYO Automation, emphasized the importance of automation in overcoming these challenges. “If you look closely at the trends,” he said, “you will see that the rush to adopt automation emerged after the COVID-19 pandemic, which was exacerbated by trade wars, leading to a new manufacturing landscape. Bottleneck challenges in China have led to a reshoring of most manufacturing businesses, and Southeast Asia is clearly the destination for relocation after the global manufacturing shortage caused by the pandemic. Thailand, particularly in the automotive and electronics sectors, is one of the countries that stand out in manufacturing.”

To address labor shortage challenges, TOYO Automation offers easy-to-use automation solutions, especially for semiconductor and electronics part manufacturing where precision and quality are crucial. TOYO products can be integrated with international software brands to deliver excellent performance and efficiency, particularly the new generation of cylinders that offer high accuracy in automation movement. The quality of these products is comparable to that of Japanese brands, as TOYO was once an OEM for Japanese products. “We are the cost-effective choice for manufacturers in Thailand who want to transform their factory with automation,” Siddhesh explained. “Whether it’s a small, medium, or large business, our automation solutions offer outstanding quality and pricing.”

‘TOYO Automation’ Leverage Semiconductor’s Manufacturing, Higher Quality for Better Competitiveness

TOYO ROBOT (THAILAND) has been founded to support both sales and services, and the company offers products that can be delivered quickly. Every product is checked and inspected before delivery to guarantee immediate usage without any worries. In MANUFACTURING EXPO 2023, TOYO Automation will present two outstanding products for automation: the JTHS desktop robot for adhesive dispensing and the CGTH high precision bearing servo cylinder.

JTHS, ball screw type desktop robot for PCB manufacturing

JTHS is a compact desktop robot specifically designed for the efficient manufacturing of electronic parts. This versatile robot excels in various tasks such as dispensing and pasting adhesive, welding, automated optical inspection, and screw tightening for small parts. The software of JTHS has been thoughtfully designed to be compatible with CAD files to reduce the setup and configuration time.

Moreover, the robot boasts high accuracy movements and can be easily configured by the user through the control panel. Its accuracy is achieved through the implementation of servo motor movement and a ball screw mechanism, which offer a superior performance compared to belt-type mechanisms. Furthermore, the JTHS robot can store up to 100 procedures and 100,000 points while maintaining a repeatability of ± 0.002 mm. For offline operation, this desktop robot can control and communicate via networking technology as I/O terminals, 16IN/16OUT with a standalone control box.

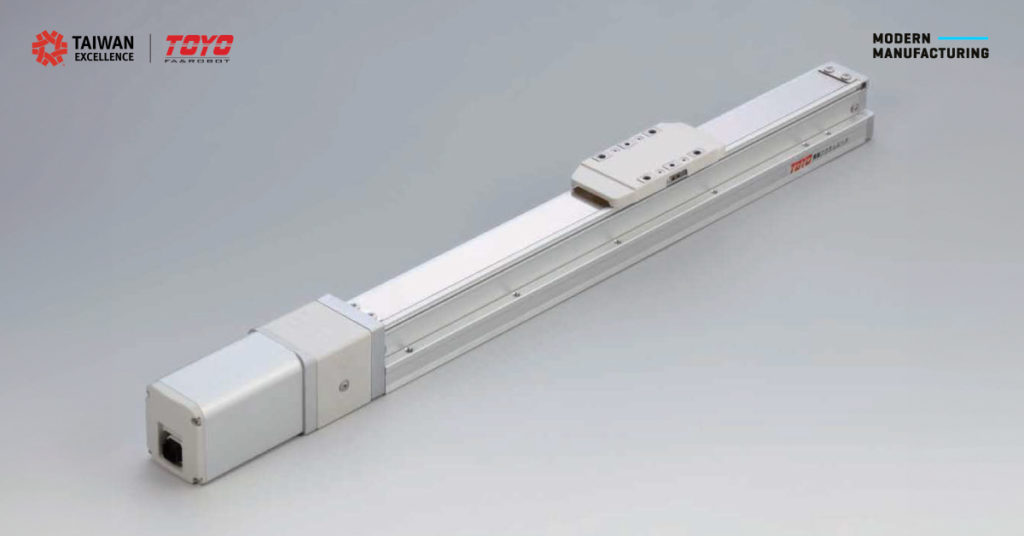

CGTH, high precision bearing servo cylinder

The CGTH is a series of cylinders developed by TOYO Automation that received the Taiwan Excellence Awards in 2018. Its compact size, high accuracy, and durability are key advantages. The body of the CGTH cylinder is made up of steel, providing exceptional durability and allowing it to operate under high loads for material handling and positioning applications. The TC100 controller can be used with the CGTH cylinder to enable three different control modes, including IO, Pulse, and Communication.

TOYO Automation has designed the CGTH as an electrified bearing servo cylinder due to the many limitations of pneumatic technology. Pneumatic cylinders generate noise and require compression and airflow checks every two to three years of operation. The two-position movement of pneumatic cylinders, A and B, is not well-suited for the current Industry 4.0 era. When compared to pneumatic cylinders, the servo designed by TOYO Automation can mark up to 127 positions, providing greater precision during operation.

Considering the rapidly changing landscape and the challenges posed by labor shortage, TOYO Automation is fully prepared to support factories in their transformation needs. Their high-performance technology is designed to be easily implemented and requires less skilled labor to operate effectively.

TOYO Automation will showcase their high precision automation technology at the Taiwan Excellence Pavilion, Manufacturing Expo 2023 in BITEC, Thailand from June 21 to June 24, 2023, between 10:00 AM to 6:00 PM. The event will feature demonstrations of JTHS and CGTH, which are aimed to improve manufacturing performances. Manufacturers who are interested in exploring these innovative technologies are encouraged to attend.

About Taiwan Excellence

Taiwan Excellence believes that only innovation can bring about change for a better life. A cross-disciplinary team of jurors search and select innovative brands in Taiwan that are breaking the mold in sustainability, design, research, and development. The Taiwan Excellence mark has become one of the world’s most coveted and recognizable symbols of quality and design, showcasing Taiwan’s outstanding product innovation around the globe. Please visit https://www.taiwanexcellence.org/th/product for more information.

Taiwan Excellence ‘Empowering Smart Manufacturing’ Product Launch @ Manufacturing Expo 2023 will start at 14:00 on June 21st in SILK 1 conference room. Click to register: https://forms.gle/QRg3kMRDSh7aBijG9