Smarter Human X Smarter Tech: ‘Technology for Everyone’ Next Step for Labor in Automotive Manufacturing Sector From GMT

Technology plays a pivotal role in enhancing competitiveness within the manufacturing industry. Technology has also been developed to support labor in terms of safety, productivity, and work quality. In line with this belief, GMT GLOBAL INC., a reputable company specializing in mold components and automation, has successfully developed technologies that facilitate the transformation of labor in modern-day manufacturing. This transformation is particularly significant for the automotive sector, which serves as a vital industry in Thailand.

The manufacturing sector faces major challenges such as labor shortages, skill deficiencies, and increasing quality requirements. These multifaceted obstacles cannot be overcome sustainably within a short timeframe without the integration of technology. By harnessing technological advancements, these challenges can be effectively addressed, thereby fostering stability and improvement across various processes. Despite the undeniable influence of technology in the manufacturing landscape, it is important to acknowledge that this trend also raises concerns among the labor force within the sector.

‘New Generation Labor’ All the Skills They Need Through Technology-Based Ecosystem

A significant portion of the labor force in the manufacturing sector must acquire new skills or enhance their existing ones to sustain their careers. However, it is important to admit that not all workers can be guaranteed success in upskilling or reskilling endeavors. Due to variations in their foundational knowledge and backgrounds, their chances of achieving success through various training programs are different. To assist them in overcoming these challenges in both training and job tasks, the utilization of the ‘right’ technology becomes imperative. The ‘right’ technology can reduce the requirement for highly specialized skills and enhance overall performance without necessitating expertise in a specific field.

With almost three decades of experience in precision mechanics, GMT GLOBAL INC., whose products have received the Taiwan Excellence Award for many consecutive years, has closely observed these transformations and identified the prevailing industry trends. Highlighting the significance of this matter, Harley Shih, Mold Component Sales Representative at GMT, emphasized, “Our intention was never to replace labor with automation or other technologies. On the contrary, technology is designed to streamline and optimize labor-intensive tasks. Numerous tasks in factories still require human operation, such as control and maintenance. In many small and medium-sized businesses, labor constitutes a major part of daily operations. For instance, automotive assembly plants rely heavily on labor, with only minimal automation. This is why we invest in research and development, striving to make labor’s work easier without any intention of replacing them.”

Adding further insights, Vic Chang, Automation Sales Representative at GMT, shared a case, “Once we provided a control box with a user-friendly interface display to a factory in the Middle East, enabling operators to easily maneuver the machine. For instance, if they need to move the position by just 5 mm, they can input the number ‘5’ directly. No coding or technical expertise is required for such a simple operation, right? Additionally, we ensure that our products are pre-installed and pre-set before delivery, significantly simplifying the installation process. We provide video guidelines for installation, and we can even assist customers with configuration remotely through the internet. By diverting our products from coding to control boxes and drives, we enable customers to achieve higher efficiency and user-friendliness.”

The advancement of technology also contributes to various aspects of labor, allowing for rapid evaluation and fostering career growth within a short timeframe. Automation and user-friendly technologies play a crucial role in empowering workers to overcome challenges and propel business growth within the current manufacturing landscape.

GMT Designed Technology and Solutions for Automotive Sector with the Advantages of R&D

Undoubtedly, labor plays a crucial role in driving opportunities and competitiveness within the manufacturing sector. Even with the integration of technology, labor remains essential and closely associated with the majority of tasks performed in factories. Recognizing this aspect, GMT focuses its efforts on research and development to create products that act as a bridge between labor and advanced technology, offering customized solutions tailored to the best interests of its customers.

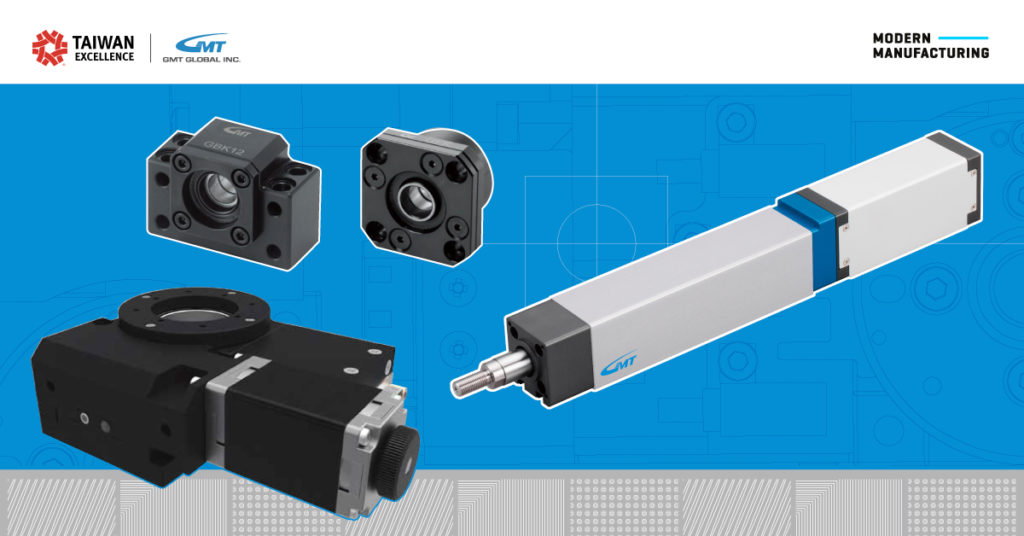

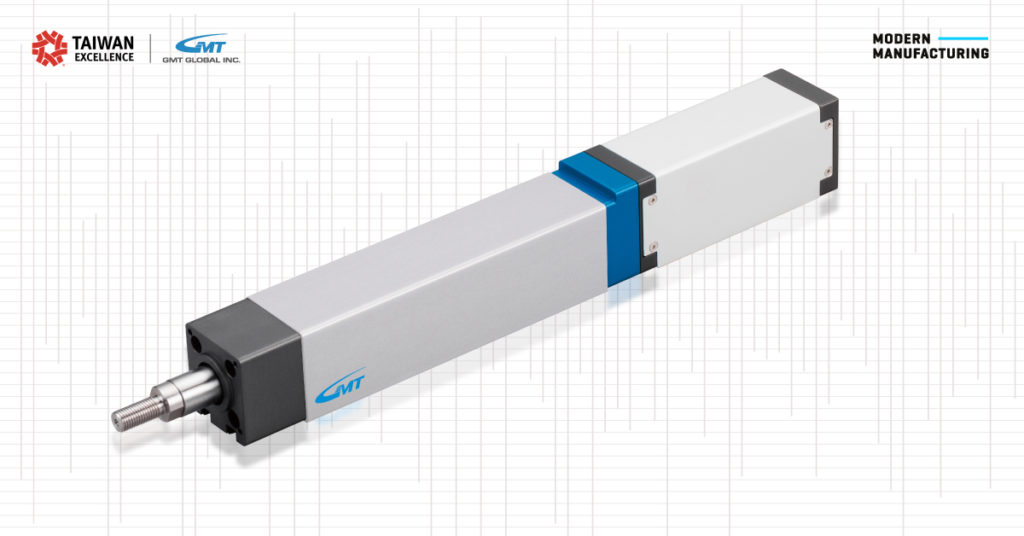

GECX Series: Electric Cylinder with Unique Patent for Enhanced Rigidity and Smoothness

An electric cylinder is a key component in automation, providing electrified motion and control with unparalleled precision compared to air cylinders, which are unsuitable for precise work. The Taiwan Excellence Award-winning GECX Series features a ball screw drive with a patented self-lubricating sleeve guide, ensuring low wear, high rigidity, exceptional smoothness, and remarkable accuracy. With their self-developed patent, the GECX Series effectively reduces vibrations during stops, and its travel stroke can reach up to 200 mm.

In addition to its high rigidity, quality, and standard features, GMT offers customers the flexibility to order customized products that cater to their specific needs. For instance, customers can choose the type of motor (servomotor or stepping motor) within the cylinder. The electric cylinders from GMT seamlessly integrate with international brands, providing hassle-free installation and setup. These cylinders are ideal for speed-focused tasks requiring precision, such as pick and place, assembly, or gluing operations.

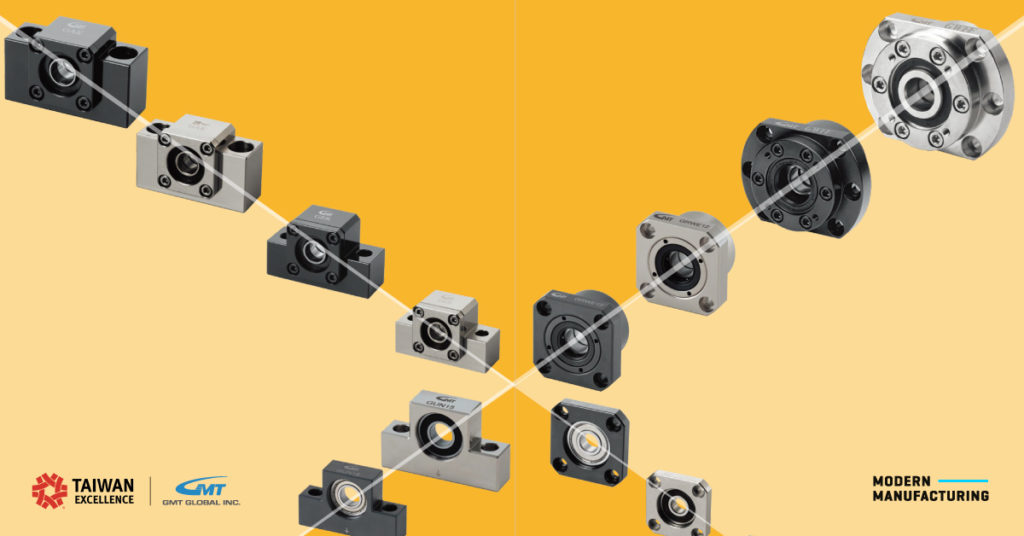

Mold Component: Enhanced Life Cycle with Reduced Downtime and Failure

Since its establishment in 1995, GMT GLOBAL INC. has excelled in the manufacturing of mold components before expanding into automation in subsequent years. Drawing upon decades of experience and expertise in precision mechanics, their mold component products encompass punches, guide pillars/bushes, ball cages, and mold bases, which can be utilized with leading machinery to optimize performance.

The advantages of GMT’s mold components lie in their exceptional rigidity and extended life cycle, which is 30% longer compared to general brands available in the market. These superior-quality components deliver value through their usage. For example, the punches exhibit higher rigidity, with wear occurring only at the head, minimizing the risk of errors or damage resulting from component breakage during the process. This reduces downtime, lowers long-term costs, improves precision when working under high loads, and saves valuable time for businesses.

The products and solutions offered by GMT GLOBAL INC. are designed with a comprehensive understanding of their system-wide usage and are formulated in a modular format. Furthermore, their products can easily integrate and collaborate with other brands. Choosing products from GMT GLOBAL INC. not only improves business growth but also enhances labor performance by providing user-friendly access to technology.

GMT GLOBAL INC., a leading provider of mold components and high-precision automation technology, is pleased to announce its participation in the upcoming Manufacturing Expo 2023. The event will be held at BITEC in Thailand from June 21 to June 24, 2023, from 10:00 AM to 6:00 PM.

During the expo, GMT GLOBAL INC. will showcase its cutting-edge products, including the GECX electric cylinder and Mold Component. These innovative solutions are specifically designed to enhance manufacturing performance and efficiency. Attendees will have the opportunity to witness live demonstrations of these technologies, gaining valuable insights into their capabilities and benefits.

Don’t miss this chance to stay at the forefront of manufacturing technology. Visit GMT at the Taiwan Excellence Pavilion at Manufacturing Expo 2023 to experience firsthand the transformative power of their advanced solutions.

About Taiwan Excellence

Taiwan Excellence believes that only innovation can bring about change for a better life. A cross-disciplinary team of jurors search and hand select innovative brands in Taiwan that are breaking the mold in sustainability, design, research, and development. The Taiwan Excellence mark has become one of the world’s most coveted and recognizable symbols of quality and design, showcasing Taiwan’s outstanding product innovation around the globe. Please visit https://www.taiwanexcellence.org/th/product for more information.

Taiwan Excellence ‘Empowering Smart Manufacturing’ Product Launch @ Manufacturing Expo 2023 will start at 14:00 on June 21st in SILK 1 conference room. Click to register: https://forms.gle/QRg3kMRDSh7aBijG9