Smarter Human x Smarter Tech: SOLOMON’s AI Solution, Transform Employees into Digital Manufacturing without Leaving Anyone Behind

In today’s manufacturing sector, competition is fierce, and businesses face a multitude of challenges. One of the key determinants of global competitiveness is the quality and quantity of labor, which can be impacted by lack of skills and experience. Moreover, the uncertainty stemming from trade wars only serves to exacerbate these issues. Against this backdrop, the adoption of new technologies, including automation and digitalization, is imperative. However, this transformation also raises the critical question of how to ensure that labor can survive and thrive in this rapidly-evolving landscape.

To address the challenges of labor in manufacturing competition, SOLOMON Technology, a Taiwan Excellence Award-winning company, has developed a cutting-edge digital solution that enhances labor skills and safety. This innovative technology holds the potential to propel businesses towards fast and steady growth by boosting productivity and transparency, while also ensuring that no worker is left behind.

‘Labor’ the challenge that can transform into advantages

The challenges faced by businesses today are vastly different from those of the past 10 years. Global issues such as trade wars, global warming, virus outbreaks, resource scarcity, and labor shortage are affecting businesses worldwide. In such uncertain times, technology has become an indispensable tool for solving many of these challenges. Today’s technology is characterized by real-time responsiveness and precision in data evaluation, which leads to waste reduction and improved outcomes in all related activities.

While technology plays a crucial role in manufacturing competitiveness, not every factory can afford to adopt or advance its use. There are many barriers to business transformation, including lack of investment and knowledge, but one of the most significant barriers is labor.

Michael Lee, the Product Director of the Vision Business Unit at SOLOMON Technology, recognizes the gap between labor and cutting-edge technology. This gap can be bridged with new technology, which not only emphasizes the true value of evaluation but also empowers labors to remain competitive in the digital manufacturing era. “We used to drive the manufacturing sector with automation and robotics, which is brilliant, but something is still missing,” Michael explains. “During the pandemic, automation usage has been rushing into the factory, but we found that some customers face challenges for installation or integration due to their technicians not being able to enter the factory. Even though the situation has improved, we are still thinking about it. This situation led us to ask ourselves, ‘Why do we need to replace humans with robotics?'”

To address this question, Michael and his team rethought the configuration of digital manufacturing from the ground up. They found that while some businesses believe that humans cannot work 24/7 and are prone to fatigue and errors, the majority of challenges relate to the inability of factories to track and trace all employee activities. This can lead to mistakes, accidents, and high potential risks that go unnoticed by management. The solution, Michael explains, is to integrate AI into smart glasses to help labor overcome these challenges on the spot. “Our smart glasses cover various tasks through AI support in real-time, while the manager can track, identify, and evaluate their work results through the glasses too,” he says.

This idea led to the development of SOLOMON Technology’s ‘META-aivi’ solution, which anyone can use without specialized skills. Employees can learn and improve their skills steadily by using this technology, even in the fast-changing economic landscape. Ultimately, this solution represents a critical step towards bridging the gap between labor and technology in the manufacturing sector.

SOLOMON Technology, Empowered Labor with Ready-to-Use AI

SOLOMON Technology, with over 50 years of experience and more than 1,000 employees worldwide, is a leading provider of smart manufacturing solutions based in Taiwan. With a team of 130 specialists dedicated to developing smart machine vision technology, the company has introduced several cutting-edge products such as the AccuPick machine vision for robot’s pick and place, which was showcased at the Manufacturing Expo 2022. Leveraging their expertise, SOLOMON Technology has developed META-aivi, an innovative solution that bridges the gap between labor and competition in modern manufacturing. META-aivi aims to improve safety and efficiency, while ensuring precise evaluation, making it an indispensable tool for today’s factories.

META-aivi smart glasses solution to empowered labor

The Taiwan Excellence Silver Award winner META-aivi seems to be a versatile and innovative solution for smart manufacturing that addresses many of the current challenges faced by factories. Its combination of wearable AI technology and augmented reality can help increase efficiency, reduce human error, and provide real-time data tracking and analysis. By using voice commands and high-speed communication, it allows for quick responses to changing situations and can be customized to fit different factory requirements.

Moreover, META-aivi can be used in various activities of manufacturing, including validation, counting, identification, inspection, and optical character recognition. This technology can also help to provide safety in the manufacturing environment and support both skilled and unskilled workers. It can even be used for new staff training to accelerate the learning process and improve the overall quality of work.

An interesting use case is shared by Michael, where a motorcycle manufacturer uses META-aivi to preserve the knowledge of skilled workers through AI training, thus solving the problem of skilled labor shortage. AI can learn from specialists in different fields and turn that knowledge into a company’s asset, eliminating the need for skilled labor in every location and standardizing the production across different countries.

Overall, META-aivi is a promising solution that can help manufacturers adapt to the current challenges faced by the industry and drive competitiveness in the digital manufacturing era.

Solvision, AI machine vision solution for one-stop visual inspections

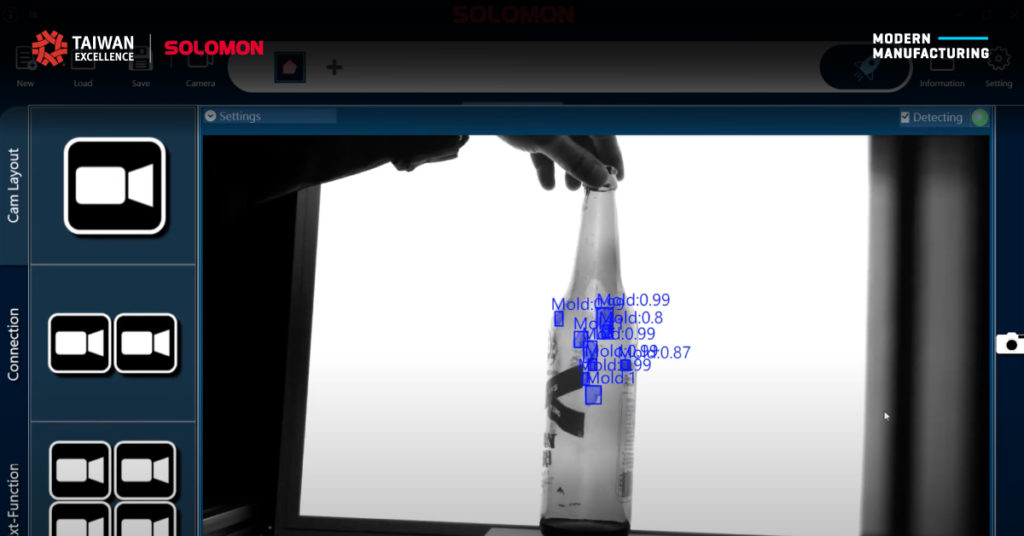

SOLOMON Technology has developed Solvision, a comprehensive visual inspection solution for machine vision that reduces the task burden of AOI’s (Automated Optical Inspection) hardware image processing. This solution can save time and cost for algorithm development in AOI, providing greater flexibility in usage.

Solvision, one of Solomon’s Taiwan Excellence Award-winning products , is a fusion of AI and 3D vision solutions specifically designed for industrial work. This intelligent vision aims at factory automation, particularly for fast-moving parts that require high-accuracy image inspection data. With built-in data augmentation, the solution requires only a few samples to train AI, while its user interface is friendly and easy to generate reports. The quality of inspection through cameras is impressive, making Solvision ideal for high-specification requirement detection, such as medical device manufacturing, where even the smallest parts demand the highest quality.

Traditional AOI systems used today often rely on coding skills for identifying good or defective parts. These systems operate based on predefined rules, which can lead to inefficiencies and waste if all possible scenarios are not covered, necessitating manual inspection by labor to double-check. AI integration, such as Solvision, allows for a more flexible work process. There will be less waste, less redundant work, and greatly improved quality inspection.

SOLOMON Technology’s products are designed to prioritize the user experience, with ease of use and a low learning curve, without requiring specialized expertise. Anyone can operate it, and labor can improve their skills with ease, while companies can reduce waste and the risk of labor shortage. Compared to high technology automation investments, their solution can reduce costs, which is a big plus for manufacturers.

SOLOMON Technology will showcase its cutting-edge machine vision solutions at the Taiwan Excellence Pavilion at Manufacturing Expo 2023 in BITEC, Thailand from June 21 to June 24, 2023, between 10:00 AM to 6:00 PM. The event will feature demonstrations of META-aivi and Solvision, which are designed to empower human capabilities in the manufacturing industry. Manufacturers who are interested in exploring these innovative technologies are encouraged to attend.

About Taiwan Excellence

Taiwan Excellence believes that only innovation can bring about change for a better life. A cross-disciplinary team of jurors search and select innovative brands in Taiwan that are breaking the mold in sustainability, design, research, and development. The Taiwan Excellence mark has become one of the world’s most coveted and recognizable symbols of quality and design, showcasing Taiwan’s outstanding product innovation around the globe. Please visit https://www.taiwanexcellence.org/th/product for more information.

Taiwan Excellence ‘Empowering Smart Manufacturing’ Product Launch @ Manufacturing Expo 2023 will start at 14:00 on June 21st in SILK 1 conference room. Click to register: https://forms.gle/QRg3kMRDSh7aBijG9